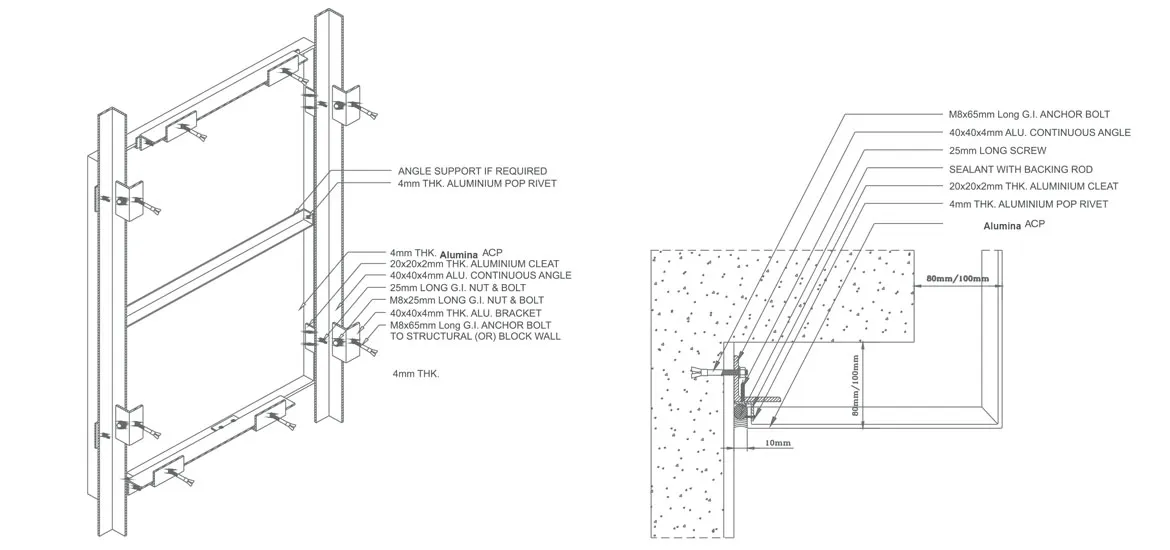

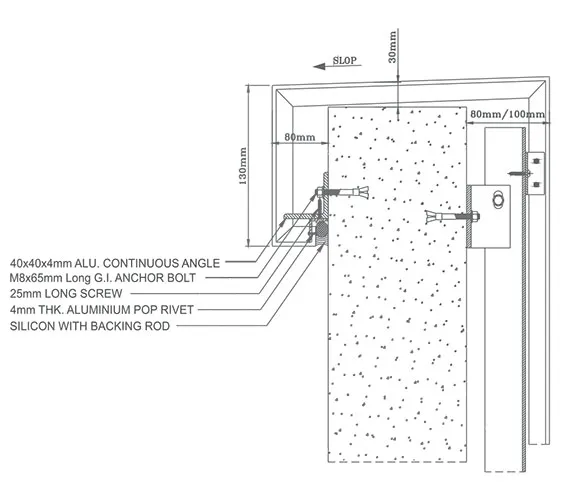

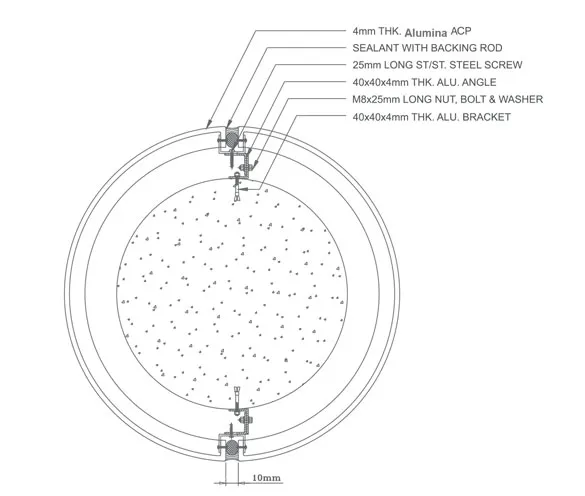

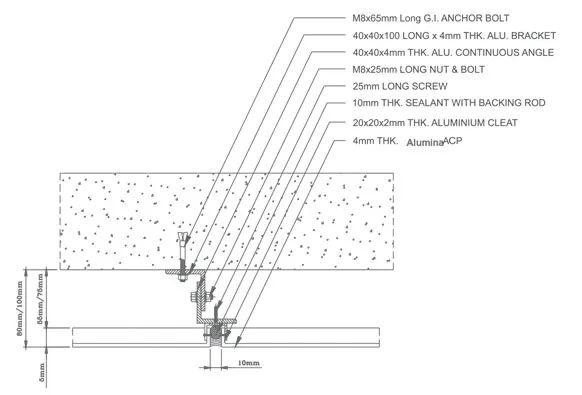

Fixing Accessories

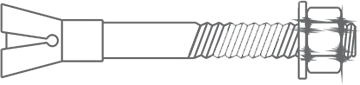

M8x65mm LONG ANCHOR BOLT

M8x65mm LONG ANCHOR BOLT

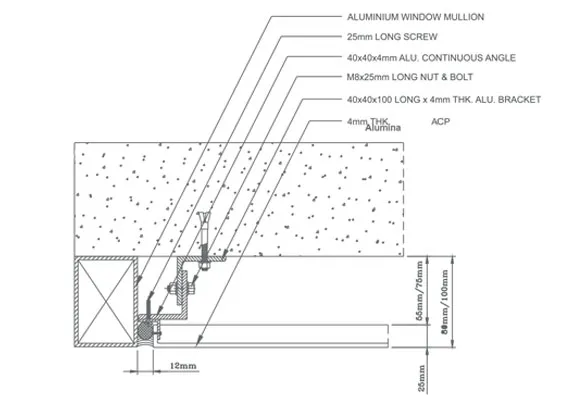

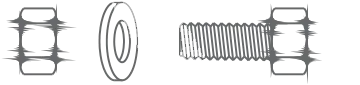

M8x25mm LONG NUT & BOLT

M8x25mm LONG NUT & BOLT

25mm LONG SCREW

25mm LONG SCREW

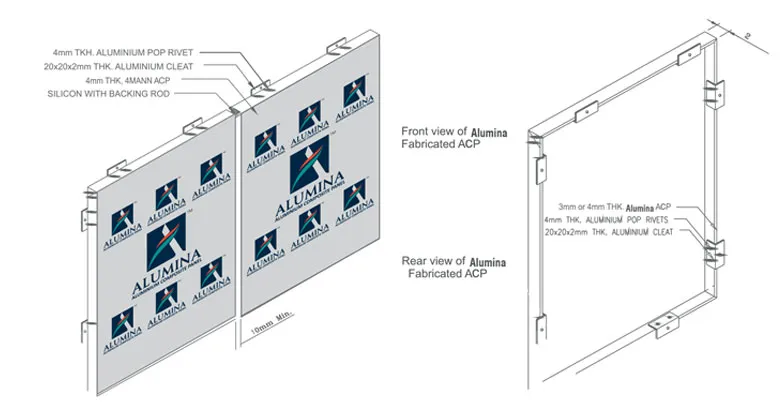

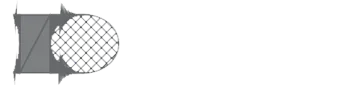

SEALANT WITH BACKING ROD

SEALANT WITH BACKING ROD

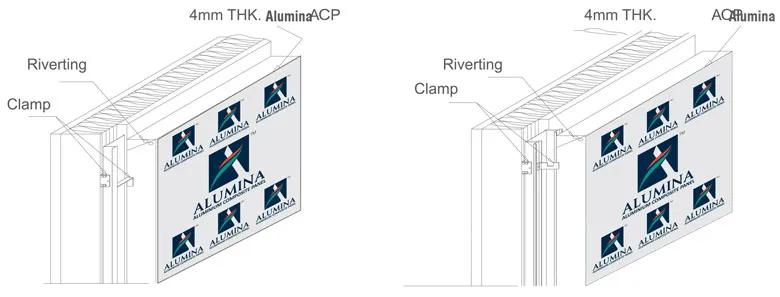

ALUMINIUM POP RIVET

ALUMINIUM POP RIVET

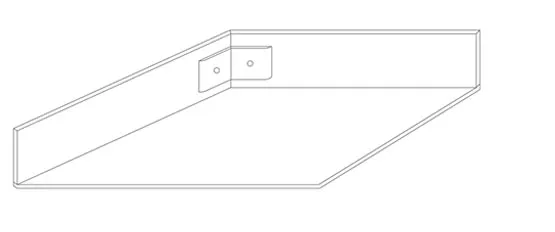

20x20x2mm THK. ALUMINIUM ANGLE

20x20x2mm THK. ALUMINIUM ANGLE

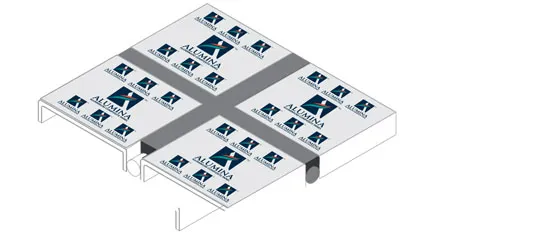

40x40x4mm THK. x100mm LONG ALUMINIUM BRACKET

40x40x4mm THK. x100mm LONG ALUMINIUM BRACKET

40x40x4mm THK. ALUMINIUM CONTINUOUS ANGLE

40x40x4mm THK. ALUMINIUM CONTINUOUS ANGLE