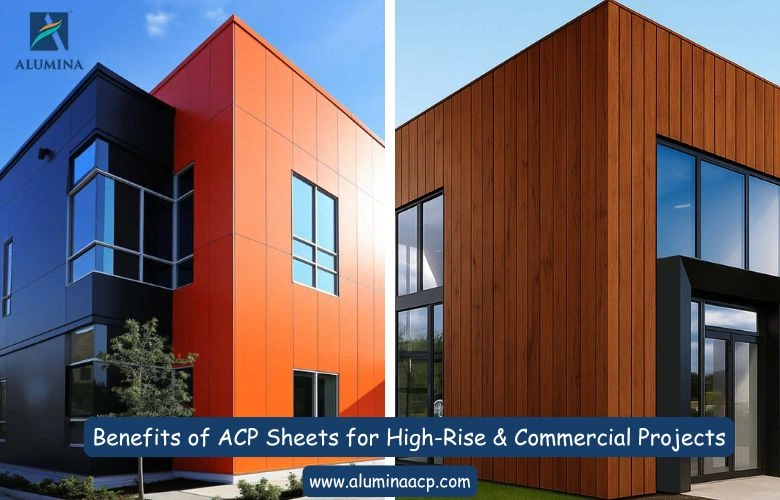

Benefits of ACP Sheets for High-Rise & Commercial Projects

When you look at a tall commercial building, what do you notice first? The height matters. The scale impresses. But it is the outer surface that creates the first real impression.

That outer layer tells a story.

Is the building modern or outdated?

Premium or ordinary?

Built to last or just built to stand?

In today’s cities, those answers often come from ACP sheets.

From corporate towers to shopping malls, ACP sheets have quietly become the preferred choice for high-rise and commercial projects. Not because they are trendy. But because they solve real problems that these buildings face every day.

Let’s understand why.

What High-Rise and Commercial Projects Really Need?

High-rise and commercial buildings work harder than most structures. They are exposed to more stress. More people. More weather. More expectations.

They need materials that can:

- Handle constant sun and rain

- Withstand wind pressure at height

- Meet safety and fire norms

- Looks good for many years

- Stay low on maintenance

Now ask yourself a simple question.

Can one material manage all this without creating future issues?

This is where ACP sheets fit in naturally.

Lightweight Structure That Makes a Big Difference

Weight is a serious concern in tall buildings. Every extra kilogram adds pressure to the structure.

ACP sheets are lightweight by design. This reduces the overall load on the building without sacrificing strength.

What does this mean in real life?

It means:

- Easier structural planning

- Safer use at higher floors

- More flexibility in facade design

That is why ACP sheets are widely used in office towers, hotels, hospitals, and large commercial complexes.

Design Flexibility for Modern Architecture

Modern commercial buildings rarely follow simple box designs anymore. They curve. They angle. They layer surfaces.

ACP sheets support this creativity.

They allow:

- Sharp edges and clean lines

- Curves and custom shapes

- Seamless panel alignment

Think of a corporate office that wants a strong brand presence. Or a mall that needs a premium feel. ACP sheets make it possible to achieve these looks without mixing too many materials.

The result is a cleaner design and a more consistent finish.

Weather Resistance That Suits Tall Buildings

Weather changes always create problems for high rise buildings, especially for the external structure. Change in temperature and moisture can tear the outer layer and damage structural integrity. But this risks becomes minimal with ACP sheets as they offer:

- UV resistance to reduce fading

- Moisture resistance to prevent damage

- Stable performance across temperature changes

Fire Safety Is Not Optional

Every year 1000s of fire accident cases are recorded only in India. Thus, the government also positioned strict regulations for safety in high rise buildings.

Thus, experienced builders and architects are using ACP sheets for enhanced safety and fire resistance. ACP sheets also known as sandwich panels scientifically reduce the chances of fire accidents as they have a chemically proven fire resistance coating over the surface.

Faster Installation Saves Time and Cost

Large projects run on tight schedules. Delays affect budgets and handover dates.

ACP sheets help keep things moving.

They are:

- Easy to fabricate

- Simple to transport

- Quick to install

Installation teams can work efficiently without complex processes. This helps projects stay on track and reduces overall construction time.

Low Maintenance for Busy Commercial Spaces

Commercial buildings cannot afford frequent exterior repairs. They disrupt operations and inconvenience users.

ACP sheets require minimal maintenance.

This includes:

- Easy surface cleaning

- No frequent repainting

- Long-lasting finishes

For malls, offices, and business hubs, this makes a noticeable difference over the years.

Long-Term Value Beyond Initial Cost

Choosing materials is not just about today’s price. It is about long-term value.

ACP sheets offer:

- Durability over time

- Lower maintenance expenses

- Consistent appearance

When viewed across the building’s life cycle, they often prove to be a cost-effective solution for large projects.

Why Alumina ACP Sheets?

Choosing the right ACP sheets matters as much as choosing ACP sheets themselves. Quality affects performance, safety, and finish.

Alumina ACP Sheets are developed to meet the demands of high-rise and commercial applications. They focus on durability, surface quality, and consistency.

Key strengths include:

- Strong and reliable panel construction

- ISO certified and meet global standards

- Fire and moisture resistant panels

- Durable coatings for long-term use

- Multiple finishes for design flexibility

- Performance suited for large-scale projects

These factors help architects and developers build with confidence.

Final Words

If you are planning your next commercial or high-rise project, explore smarter panel solutions. Discover Alumina ACP Sheets and browse our catalogue to find the right fit for your building vision.

Frequently Asked Questions

ACP sheets are aluminium composite panels used for building facades, cladding, and interiors. They combine strength with a modern appearance.

They are lightweight, durable, and visually versatile. This makes them suitable for large commercial and high-rise projects.

Yes. ACP sheets are commonly used on building exteriors because they resist weather and pollution effectively.

Good-quality ACP sheets can last many years with proper installation and basic maintenance.

No. They are easy to clean and do not require frequent repairs or repainting.

PREVIOUS BLOG

NEXT BLOG

Leading ACP Sheet Manufacturer

As a proud representative of Alumina ACP, a premier manufacturer of Aluminum Composite Panels, I bring a wealth of expertise in acp sheets and addressing diverse architectural needs with innovative solutions. Join me on this journey of exploration and discovery!